Capacity List

View our machining and Technical capabilities

Star-SR20JII TYPE A

The SR-20JII Type A offers improved rigidity, accuracy and versatility through a combination of enhanced engineering and expanded functionality.

Combining a 6-tool turning platen with a 5-spindle cross drilling unit and a 4-spindle back working tool post, the SR-20JII boasts excellent tooling capacity allowing for a vast range of machining options.

MAIN SPINDLE SIDE

- Number of Axes: 7

- Main Spindle (Headstock) Z1 / C1 AXIS

- Tool Post X1 / Y1 AXIS

- Max. Machining Diameter: 20 MM / 22.2 MM (Option)

- Headstock Stroke (Swiss Type / NGB Mode): 205 MM

- Main Spindle Speed: 10,000 RPM

- Power Driven Tool (PDT) Positions: 3 + 2 Modular Stations

- Max (PDT) Speed: 8,000 RPM

SUB SPINDLE SIDE

- Sub Spindle: X2 / Z2 / C2 AXIS

- Max. Chucking Diameter: 20 MM / 22.2 MM (Option)

- Sub Spindle Speed: 10,000 RPM

- Back-Working Platen Positions: 4

- Power Driven Tool (PDT) Positions: 4 (ER16)

- Max (PDT) Speed: 8,000 RPM

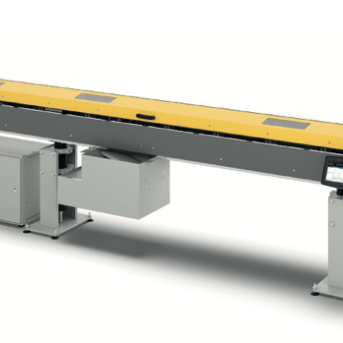

Turbo Barfeed 2-20

The FMB Turbo 2-20 bar feeder suits bars diameters 2mm up to 23mm.

- Maximum Bar Length : 3200mm

- Fast bar reload routine – bar change time 26 secs

- Suitable for round or profiled material

DMG MORI CLX 350 V6

- Highly dynamic spindle drive with max. speed up to 5.000 rpm

- Sub spindle as integrated motor spindle max. speed up to 5.000 rpm.

- Y-axis with travel range ± 40 mm for superior milling operations, i.e. for complete lateral surface machining

- ø65 mm bar capacity

- Part catcher for parts up to ø65 x 200 mm and weight 3 kg

MSV65 Barfeed

The MSV65 is a full servo-driven Barfeed eliminating the need for compressed air.

Unrivalled performance and accuracy, with a user-friendly set-up, provides the machine tool’s increased productivity.

- Bar diameter : 5-65mm

- Bar length* : 200-1550mm

- Magazine capacity : 600mm

- Magazine : Front or Rear

- Drive : Servo motor

MORI SEIKI CL-203

- Turning diameter: 310mm

- Bar work capacity: 65mm

- Rpm: 3500

IEMCA Barfeed

The KID 80+ is a short bar feeder for fixed headstock lathes ideal for lathes with sub-spindles. Suitable for working bars with diameters between 5 and 80 mm and with lengths from 250 to 1,615 mm. It is designed to meet the needs of applications for the accurate loading of short bars within a small space. simple to use and very fast.

CAD/CAM

- FUSION 360 / START NCA

- Integrated CAD, CAM and CAE software

Fanuc Control

Highest quality – shortest processing time.

With multi-axis, multi-path, and high-speed high-precision machining requirements, the FANUC 32i-MODEL B controls are ideal for highly complex machines.

The hardware and innovative software offer the highest levels of performance, precision, and surface quality.